|

Keywords |

|

HMI, Industrial Robot, Modbus TCP, Modbus RTU,

DeviceNet, EtherNet/IP, PROFINET |

|

Background |

|

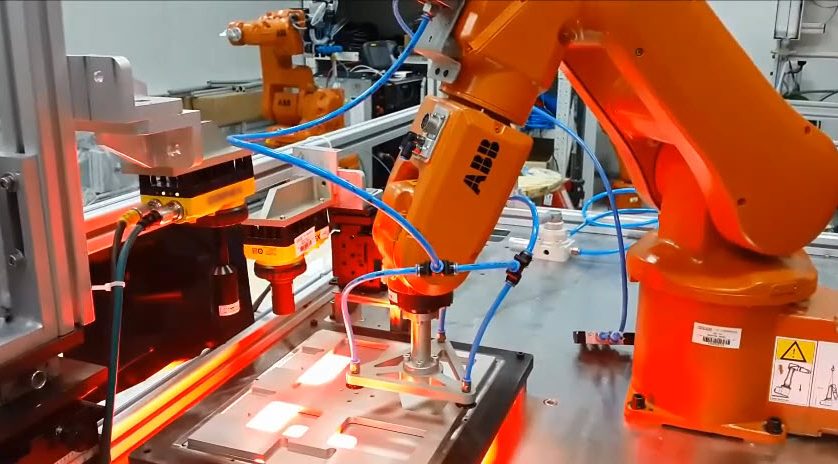

Intelligent robots are commonly used in the modern manufacturing

industry and they are very active in a variety of production lines.

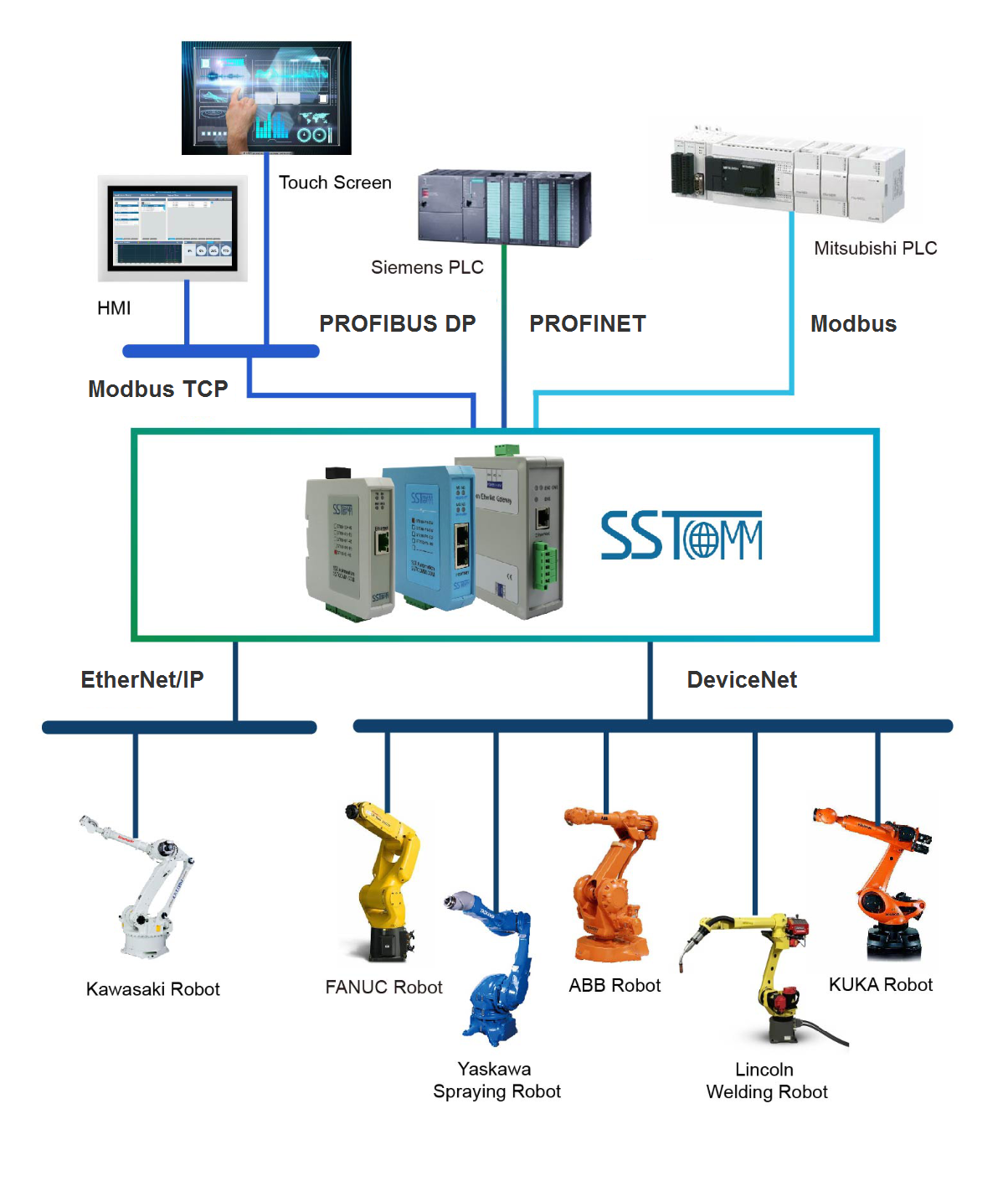

Just as humans speak different languages, robots also have their own

languages, which are called "protocols". Industrial robots can

communicate with other machines in specific protocols, such as

Modbus TCP, Modbus RTU, DeviceNet, EtherNet/IP, PROFINET, etc. |

|

Industrial robots are multi-joint manipulators or

multi-degree-of-freedom mechanical devices widely used in the

industry. They have intelligent control capabilities that achieve

various commands and actions within industrial production and

manufacturing. Common industrial robot brands include ABB, KUKA,

FANUC, Kawasaki, Yaskawa, Siasun and Lincoln (welding robot).

However, industrial robots of different brands usually use

different

communication protocols. In actual factory conditions, it is

necessary to connect multiple robots with PLCs based on different

protocols to communicate data through out the plant. But how can one

achieve these complex applications? SST Automation's GT100 and GT200 series

industrial gateways can easily solve these problems. SST Automation's gateways support many types of protocols, covering most of

the commonly used industrial communication protocols and networks

around in the world. |

|

|

Industry |

|

Mechanical Processing, Metallurgy, Automotive, Smart Building, Food

Packaging, etc. |

|

Solution |

| In

the manufacturing and processing production line, SST Automation's

industrial communication gateways can easily connect many types of devices including HMIs (Modbus TCP), FANUC robots, ABB robots

(DeviceNet), Siemens PLCs, Mitsubishi PLCs, Yaskawa spraying robots,

and more. They can also receive real-time statuses,

control the robots to complete the production process, and

facilitate the operator to monitor the production data remotely.

|

|

|

|

California Office:

3200 E Guasti Rd, STE 100, Ontario, CA 91761

Tel: 909-977-2988 (US & Canada)

+1 (626) 899-6290

(International)

|

Asian Pacific Office:

6E, Bld 3, 518# Xinzhuan Rd, Songjiang District,

Shanghai 201612,

China

Tel: +86-18917828842

|

|